steel ball for drop test|impact and drop testing : white label The high magnetic permeability of this low carbon mild steel provides good magnetic holding power. When the electricity used to excite the magnet is turned off, the ball drops, imparting an exact foot pound force on the test specimen. 16 horas atrás · Download Euphoria by Golden Drill at Juno Download. Listen to this and millions more tracks online. . The usual price for a FLAC is £1.65 per track. ALAC. .

{plog:ftitle_list}

Resultado da Yes, the word 'aloud' is several hundred years older than 'out loud'. However, 'out loud' is fully established. It may not appear as often as 'aloud' in .

collision means a perfect rebound after impact. To explain this, suppose a steel ball bearing is dropped from a certain height onto a foam pad. Since it penetrates the material, the material is absorbing the energy and thus the impact force is minimized and is therefore not a perfectly .

The high magnetic permeability of this low carbon mild steel provides good magnetic holding power. When the electricity used to excite the magnet is turned off, the ball drops, imparting an exact foot pound force on the test specimen.The Impact Test Ball is a specially machined ball to test impact resistance according to IEC, CSA and UL Standards. It is made of chrome-plated-steel for durability, and is fitted with an eyelet to facilitate testing for pendulum . This video demonstrates UL-60950 ball-drop test on Promate Diamond Series 7" and 12" Touch Display module, using a half-kilo (542g) steel ball dropped from a height of 1.3 .

This method has been used for decades for evaluating impact resistance of wood panels and other building materials. It involves a 2-inch steel ball weighing 1.18 lbs (535 g) dropped from 1 to >12 inches.

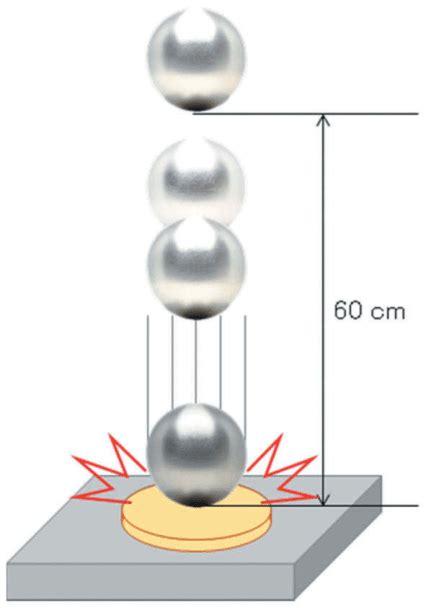

Impact testing. Haag engineered this unique system to impact target locations precisely on every drop. Our AccuDrop® steel ball tester helps perform UL 2218 tests faster, using fewer test . The Ball Drop Test is a simple and convenient way of imparting a known impact force to test the strength of various materials. Engineers and designers use it. The steel ball drop test is used to determine the impact force of a falling object on a surface. It is commonly used in materials testing and engineering to evaluate the strength .

As an example, the IEC 61965 glass safety standard for cathode ray tubes employs a steel ball and pendulum form of impact testing to simulate breakage. In this case, the failure mode is . The Ball Drop Test is a simple and convenient way of imparting a known impact force to test the strength of various materials. Engineers and designers use it.

Model XB-OTS-2000A Impact capacity: 20gf, 30gf, 50gf, 100gf or specified Effective dropping height: 300~1000mm Control method: Electric Dimension (WxDxH)

The Drop Ball Impact Test is a widely-used method of evaluating the impact resistance and overall toughness of various materials like plastics, glasses, ceramics, and even metals. . To conduct this test, a steel ball with a specific .Drop Test Balls — Drop Test Hammers — Impact Test Balls — Swing Test Balls . The most frequent impact test hammer is a precision mild steel ball. The ball is held at a specific elevation by an electromagnet. The high magnetic permeability of this low carbon mild steel provides good magnetic holding power. When the electricity used to . The hack has been dubbed “the mercury ball test,” and it involves a way to make stainless steel cookware virtually nonstick. To perform the mercury ball test, preheat your pan and dribble a few water drops into it. If the water sizzles and evaporates, the pan isn’t ready yet.A test inspired by Robert Bastow when he commented on anvilfire by saying, "You could bounce a 1" steel ball off the monitor!". Obtain a steel ball bearing ball (1/2" (13mm) to 1"(25mm)) in diameter. Drop (DO NOT THROW) the ball 10" onto the face of the anvil. On a really hard anvil the ball will bounce about 75-90% of the distance dropped.

1.1 This test method covers the destructive ball drop testing of laminated flat glass products intended for use in architectural glazing applications. 1.2 This test method is intended for use as an in-plant quality control test to evaluate the impact performance of laminated flat glass when a 2.3 kg, 83 mm diameter smooth solid steel ball is .

impact testing balls

Drop Orientation: The package is dropped in specific orientations to test its strength from various angles. Common orientations include flat on each face, on edges, and corners. Conducting the Drop Test: A drop testing machine or a free-fall method is used to ensure precise and repeatable drops. The method of dropping (manual or mechanical .

The UL 2218 impact test standard is a steel ball drop test to evaluate the impact resistance of prepared roof coverings. The Class 1 projectile is 1.25 in. in diameter, Class 2 is 1.50 in., Class 3 is 1.75 in., and Class 4 is 2.00 in. in diameter. These steel balls are dropped from the height necessary to achieve the same kinetic energy a Drop ball test for dress eyewear: a 0.56 oz 5/8 inch steel ball dropped from a height of 50 inches. Drop ball test for Basic Impact safety lenses: a ONE inch steel ball dropped from a height of 50 inches. High Velocity Impact test for High Impact lenses: a 1/4 inch steel ball hitting the lens at 150 feet/sec.For a simple drop test, where m = mass, h = drop height, g = acceleration of gravity, and v = velocity at impact, the conservation of energy equation is: . collision means a perfect rebound after impact. To explain this, suppose a steel ball bearing is dropped from a certain height onto a foam pad. Since it penetrates the

The steel ball drop test is commonly used in product development to test the durability and impact resistance of materials. It can help engineers and designers determine the strength of a material and make necessary improvements to ensure its reliability and safety in real-world applications. 5. Are there any safety precautions to consider when .

This device is suitable for drop impact testing for equipment casings. Test Sample Light sources, audio, video and similar electronic apparatus, information technology equipment . Equipment can carry out testing in two forms: vertical drop and swing impact tests. Parameters 1. Impact steel ball: diameter 50mm, 500±25g 2. Drop height: 0.5-1 .38mm Steel Ball for Tempered Glass Testing Steel Ball 2260g 227g 1040g 508g 227g Ball drop test device for safety glass Steel Ball: 2260g±20g 82mm Steel Ball: 1040g ±10g 63mm Steel Ball: 508g±3g 50mm Steel Ball: 227g±2g 38mm. Various testing equipment such as shot bags / twin tires and impact frame, 227 and 2260 g steel ball and ball drop impact devices, .2.3kg (+/- 0.1kg) 83mm diameter smooth solid steel ball, support frame (see Figure 1 ASTM F3007-19), mechanism for ensuring the unimpeded drop of the ball, calibrated micrometer. (See ASTM F3007-19 Section 6 for more details) (see . Ball Drop Test laminated glass - This is only the testing procedure, the specification should still refer to . Also, the ABS from the boxes was characterized by taking out two standard ISO 527 type-1 test bars from a separate box and performing tensile testing. Drop Test Facility and Set-up. The drop tests described here were .

TEST ARRANGEMENT The ball drop impact test apparatus (fig. 1) subjects a primary explosive to an impact of a free-falling steel ball. The standard sample size is 30 mg for each trial. A 0.75-in. diameter, 1- oz, 316 stainless steel ball is normally used. The steel ball is guided on a ball track that rises 32 in. vertically from a steel base. Drop tower testing was performed on borosilicate glass plates to determine the effectiveness of an elastomeric polyurethane/urea coating against impact and to improve our understanding of how the . The utility model discloses a steel ball drop test device for testing the glass strength of a touch screen. The steel ball drop test device comprises a test platform (1), a support (2) and a cross bar (3) with a through hole, wherein the lower end of the support is arranged on the test platform or on one side of the test platform, and the cross bar (3) with the .

Ball drop test. We also tested the impact resistance of glass and wanted to see how robust 3 mm chemically tempered glass can actually be. An approx. 500g heavy and 2" thick steel ball was used, which we dropped from different heights (between 55 - 250 cm) onto a touchscreen. So much in advance: we were more than satisfied with the result.Steel Ball 2260g 227g 1040g 508g 227g . Steel Ball: 2260g±20g 82mm Steel Ball: 1040g ±10g 63mm Steel Ball: 508g±3g 50mm Steel Ball: 227g±2g 38mm Ball drop test deive for safety glass. Various of Safety Glass Test Device: Shot Bag Impactor. Headform Test Device. Ball Impact Test Frame. Shot Bag Impactor Frame. High Temperature Test Oven . These practical requirements to determine large scale DFS of a TGP can be achieved in ball drop impact (BDI) testing that applies single steel ball impact and full-edge constraint to a specimen [[12], . in the ball drop test, it was about 1.7–3.1 ms. There was a fairly different loading duration on the order of 10 4 between the two tests .We are best Steel Ball Dropping Test Device suppliers,we supply best Steel Ball Dropping Test Machine for sale. We would like to establish the long term win-win relationship with customers from all over the world. . For testing the mechanical strength and the impact strength by pendulum test and by drop test, according to IEC60598 Fig 21 .

Pick up a steel ball by sticking it to a freshly washed finger and drop it into the capillary tube. This works better than using forceps. When dropped into the capillary, the tiny ball is usually stuck at the air-liquid interface. Use a magnet to move the steel ball below the meniscus and to a desired position inside the test solution.0.33 mm height (Figure 2). Steel balls with diameters of 0.50 inch (1.27 cm, 8.35 g) and 0.75 inch (1.91 cm, 28.20 g) were used. For every steel ball, a different steel ball guide was used to ensure a proper drop [26]. Any visual observation of decomposition was consid-ered a positive result. After each trial, the remaining materi-In the test, a metal ball of 500g with a diameter of 50mm has been dropepd from a height of approx. 130cm and hit the monitor without leaving any visible damage or even splitting the glass of the touch screen.E643-24 Standard Test Method for Ball Punch Deformation of Metallic Sheet Material . . E436-03(2021) Standard Test Method for Drop-Weight Tear Tests of Ferritic Steels . . E381-22 Standard Method of Macroetch Testing Steel Bars, Billets, Blooms, and Forgings .

impact and drop testing

WEBWelcome to Only Trans! We are so happy to have you here with us today. If you like our content and want to show your support, don't forget to subscribe and l.

steel ball for drop test|impact and drop testing